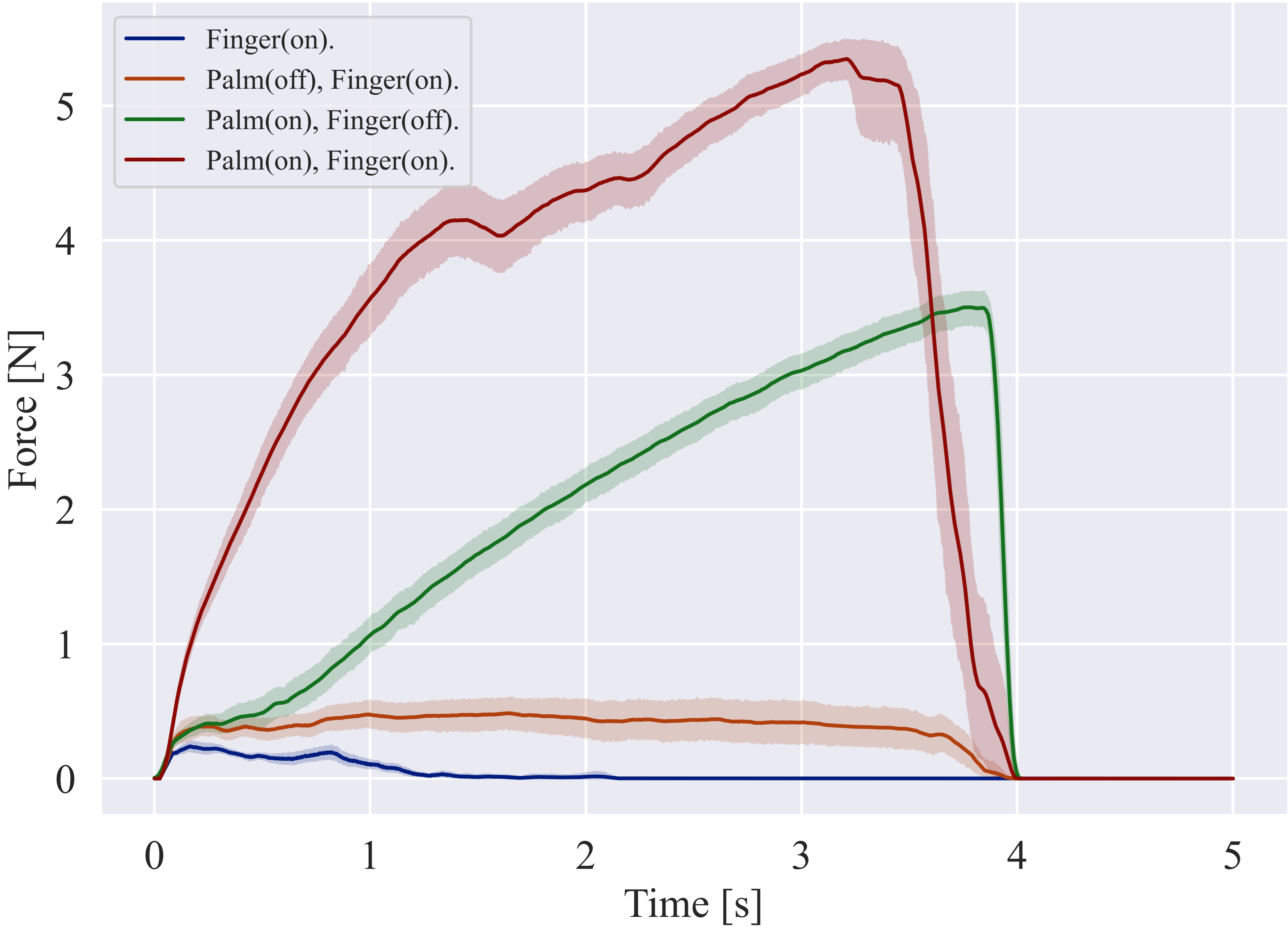

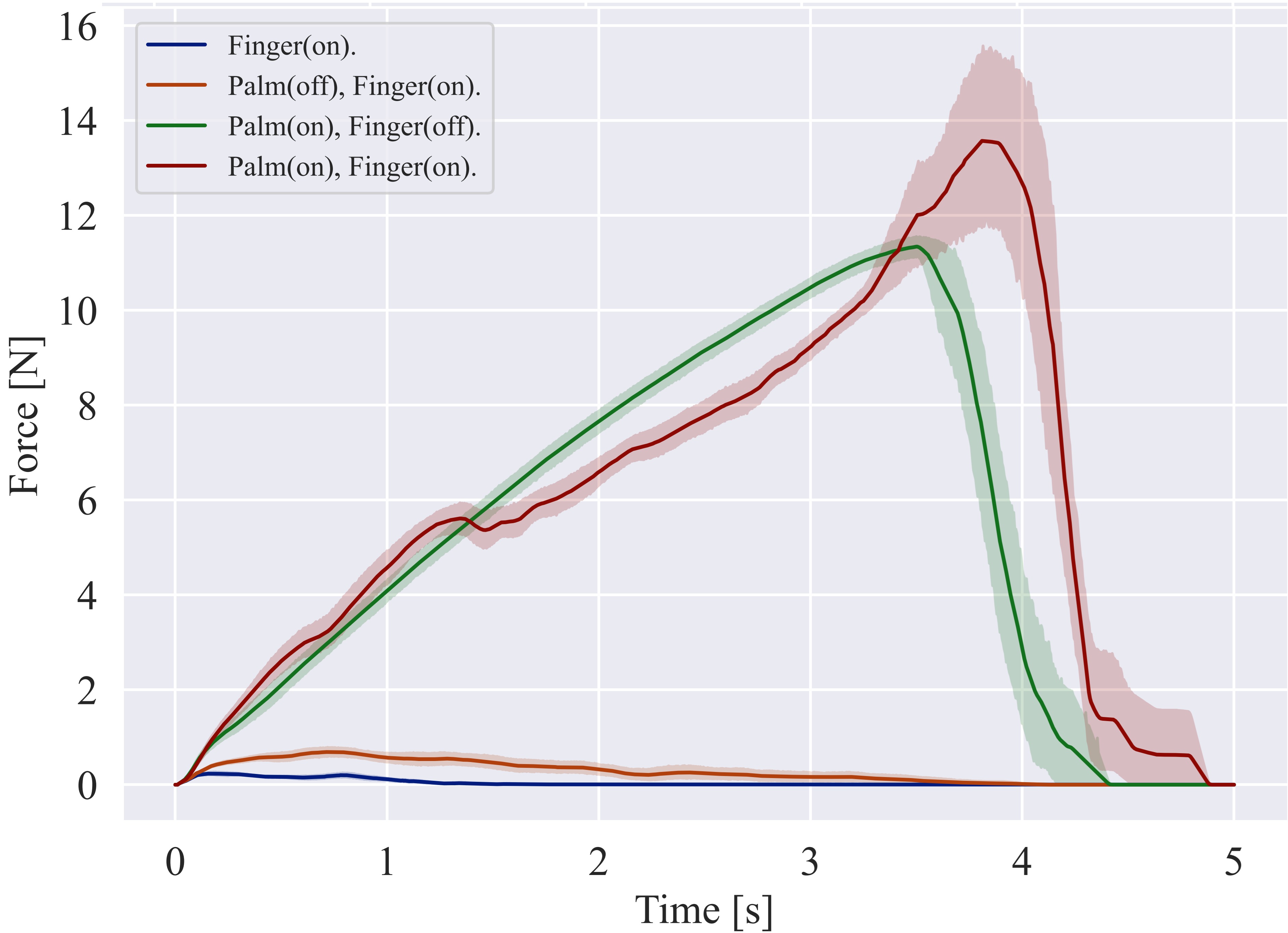

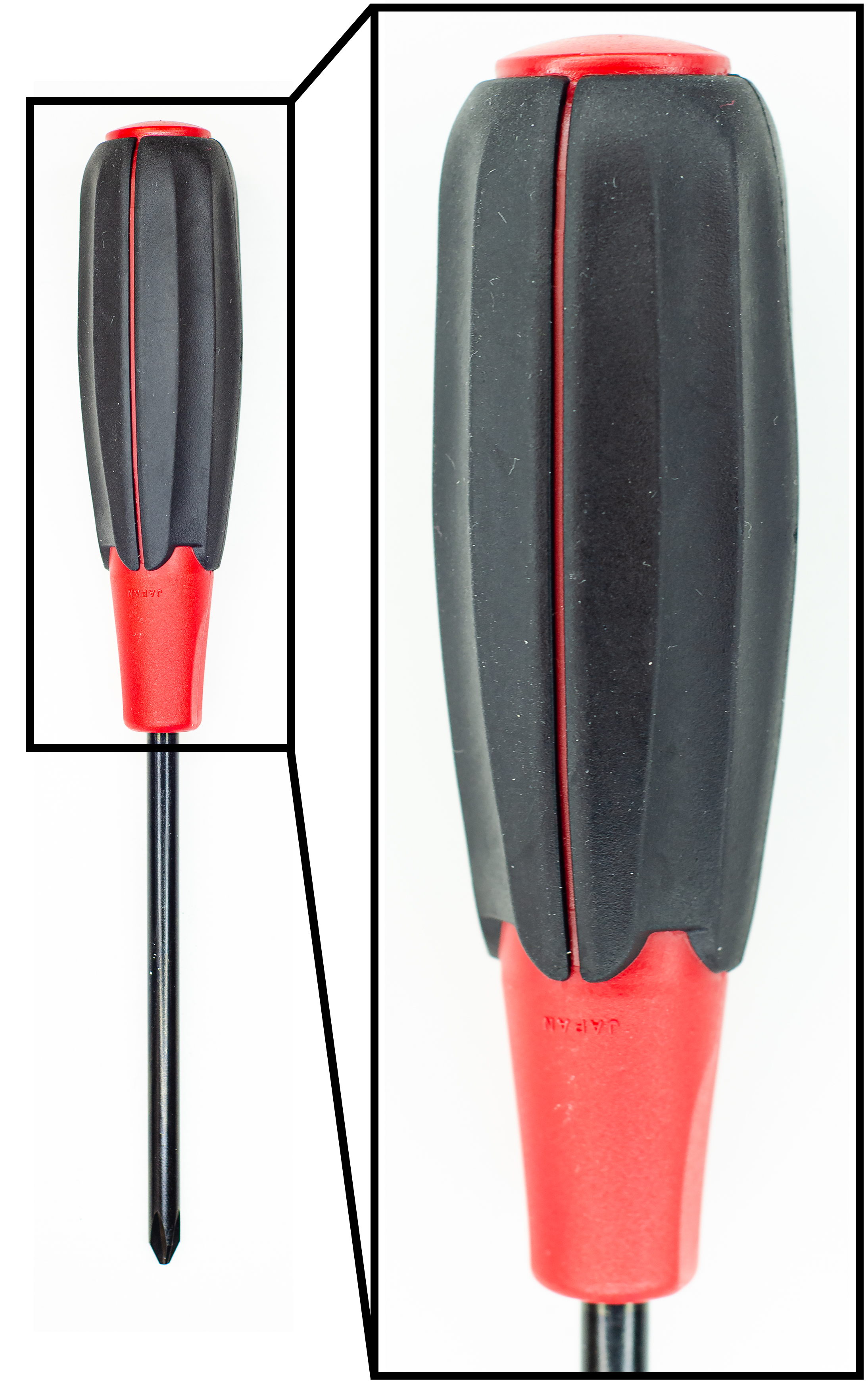

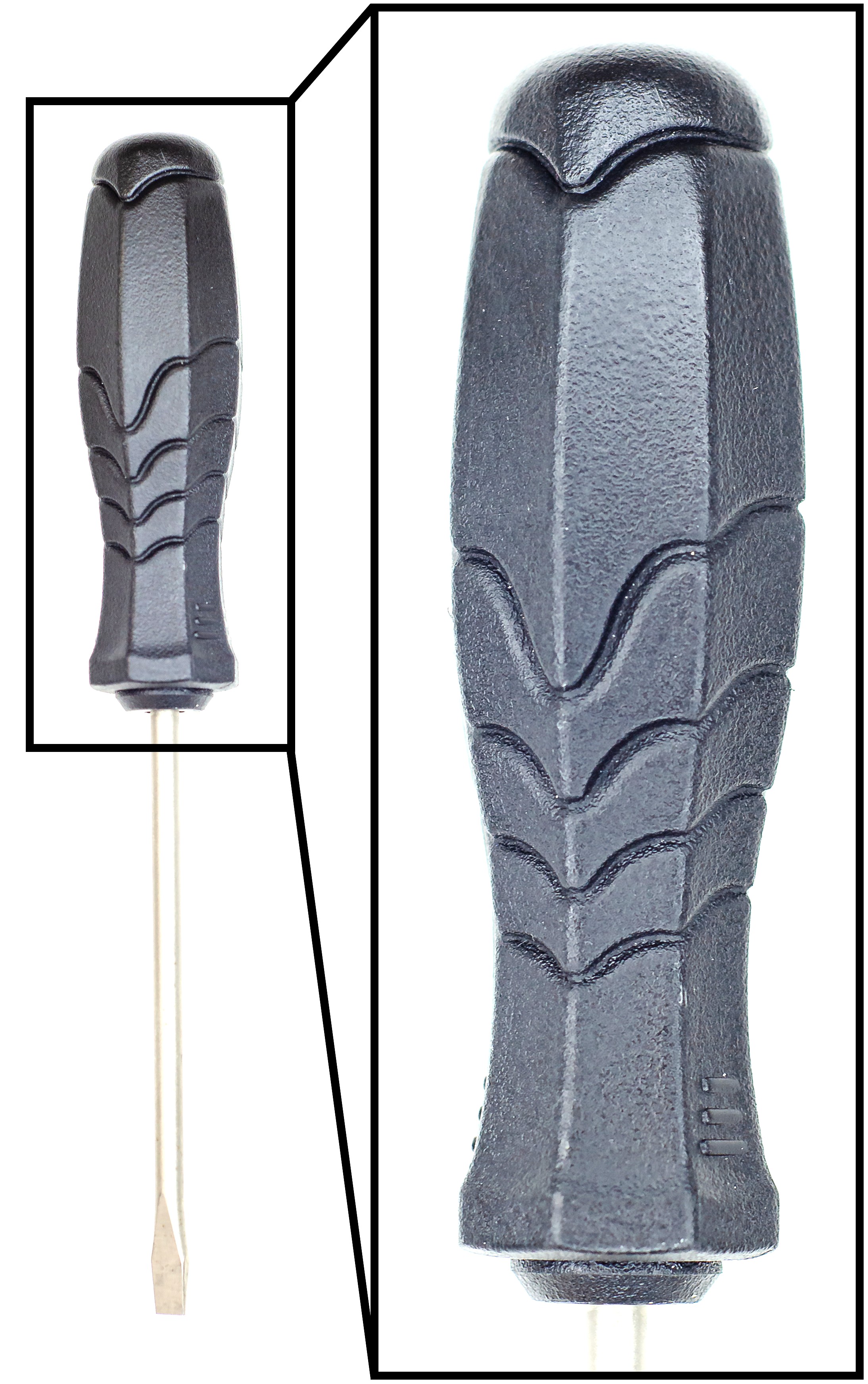

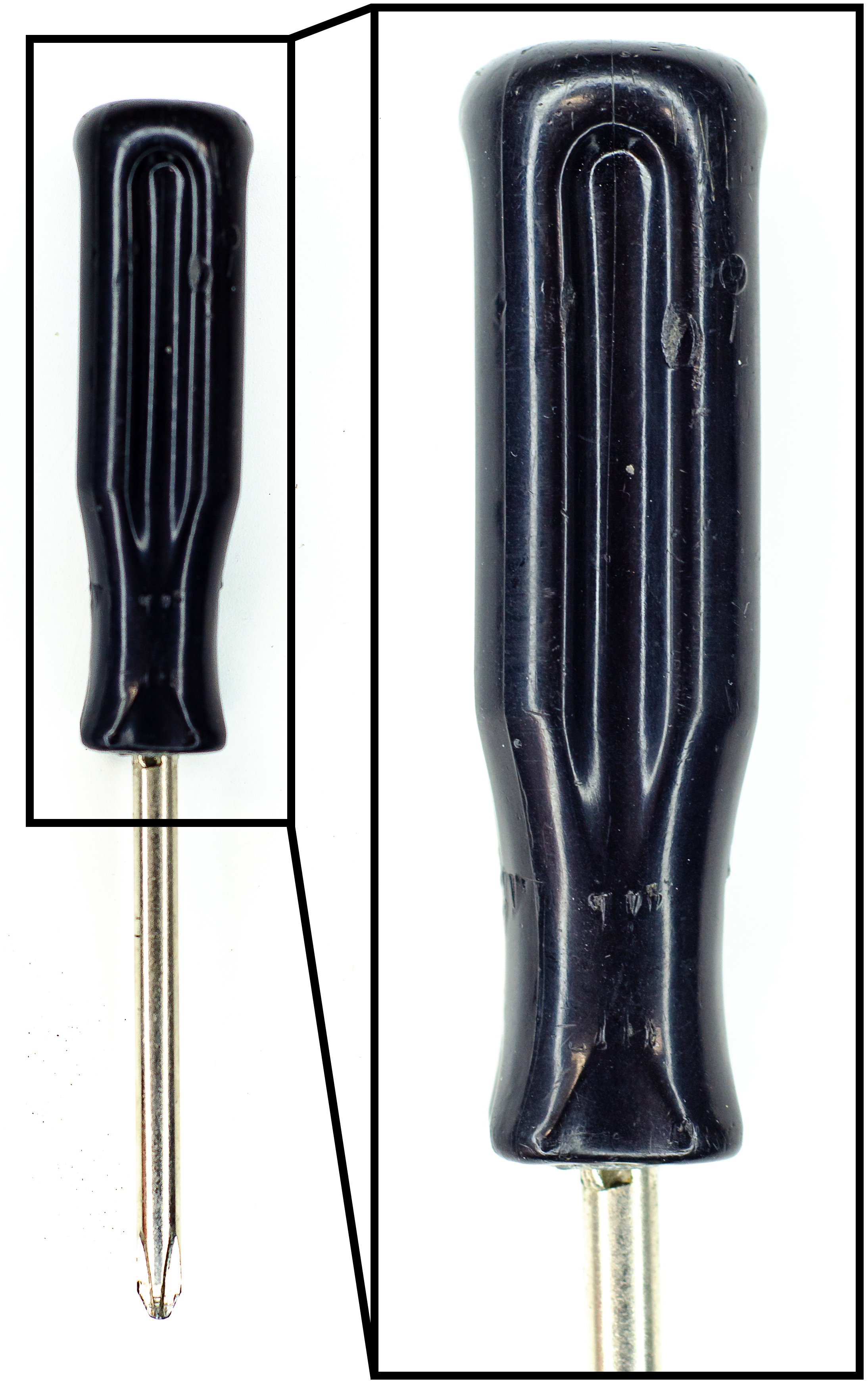

Grasping and holding tools while using them presents a considerable challenge not only for robots but also for humans. Such a challenge is particularly noticeable in processes involving assembly and disassembly, where efficiency and consistency depend on performing rapidly adaptive tasks. Nonetheless, contemporary robotic grasping technologies that can securely manipulate tools during operation frequently have significant constraints. In this paper, we introduce ARTiS (Adaptive Robotic Tool Gripper in Disassembly Systems), a novel gripper that combines the adaptability of soft grippers, the dexterity of anthropomorphic hands, and the robustness of rigid mechanisms with a soft palm. This unique combination makes it possible to hold tools securely in a variety of situations through using active jamming in the palm and fin-ray adaptation in fingertips. Furthermore, high finger dexterity is achieved through the seven degrees of freedom design, which enables the fingertips to orient themselves to any surface, both for automated solutions and collaborative tasks. We conducted a comprehensive evaluation using a range of conventional disassembly tools to assess the gripper's compliance, durability, and functional versatility.

@misc{mykhailyshyn2025artis,

title = {ARTiS: An Adaptive Robotic Gripper for Enhanced Tool Manipulation in Disassembly Applications},

url = {http://arxiv.org/abs/},

doi = {10.0/arXiv.},

publisher = {arXiv},

author = {Mykhailyshyn, Roman and Domae, Yukiyasu and Harada, Kensuke},

month = dec,

year = {2025}}